1. Determine the type of animal laboratory

According to the requirements of the national standard, biosafety

laboratories are divided into 4 levels, namely 1, 2, 3, and 4 biosafety

laboratories. Among them, the third and fourth biosafety laboratories are

high-level biosafety laboratories. Corresponding to different types of

experiments to determine different types of laboratories is the first

consideration in the design of high-level biosafety laboratories.

2. Laboratory layout

In addition to meeting the standards and requirements of relevant national

departments for the site selection and internal layout of the biosafety

laboratory, full consideration shall be given to the special requirements of

biosafety. If necessary, the recommendations of the fire control department

shall be consulted in advance. The safety and security of the laboratory shall

comply with the safety management regulations and requirements of the relevant

national departments for such facilities. The specific requirements and measures

are as follows.

The reasonable layout of the biosafety laboratory should make the work

convenient for the staff and meet the needs of laboratory biosafety. When

designing a biosafety laboratory, the relevant experimental risk assessment must

first be made. According to the risk location of the laboratory's biological

safety level, appropriate experiments are determined by risk assessment of

pathogenic microorganism types, dosages, experimental methods, and whether to

conduct animal experiments. In the early stage of design, it is necessary to

fully communicate with users to understand their work habits and operation

process in detail. For example, when designing an animal biosafety laboratory,

it is also necessary to understand the physiological characteristics and living

habits of the animals raised in the animal laboratory. Under the premise of

ensuring biological safety, the process flow should be simplified as much as

possible to facilitate work, energy saving and environmental protection.

Reasonably planning the layout of the laboratory, it is very important to

determine the flow of various elements, including personnel, animals, and

objects. Each element can be defined as clean, possibly contaminated or

definitely contaminated in different areas. Therefore, different countermeasures

need to be considered in the design of each area to ensure that all elements are

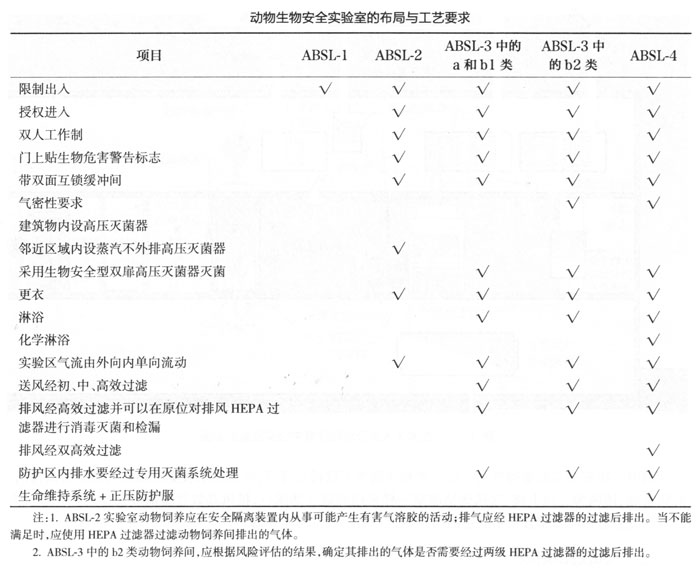

clean when leaving the experimental area. See Table 1-2-1 for details.

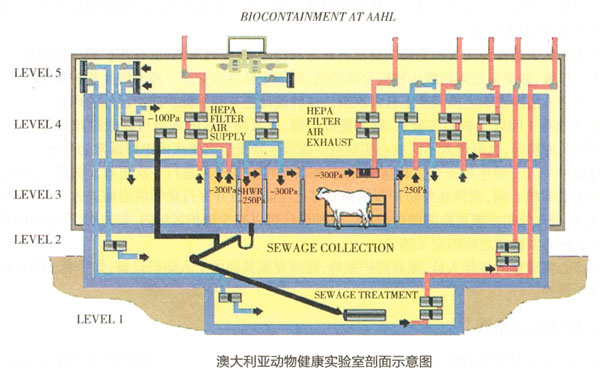

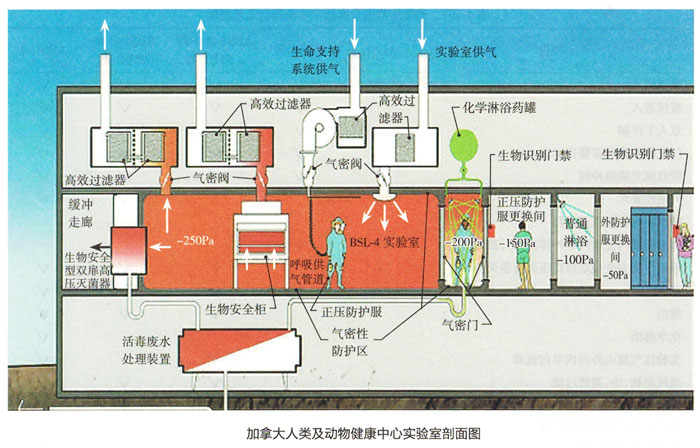

The cross-sectional layout of high-level animal biosafety laboratories usually adopts the structure of 3 to 5 vertical functional partitions. The top is the high-efficiency air filter and air conditioning equipment layer (1~2 floors), the middle layer is the laboratory biosafety protection zone, and the bottom of the first floor is the live toxic wastewater treatment room and the live toxic wastewater pipeline interlayer (1~2 floors). See Figure 1-2-1 and Figure 1-2-2.

Domestic biosafety laboratories are usually one floor. The laboratory usually does not have a drainage pipe, and the experimental wastewater is collected and sent out through an autoclave. The air supply and exhaust in the laboratory are from the top to the bottom. The air supply adopts a high-efficiency filter outlet like a clean room, and the exhaust high-efficiency filter is placed at the exhaust outlet. The high-efficiency air filter and the air duct are arranged in the ceiling of the laboratory, and the space is small and not easy to maintain.

3. Personnel entry and exit routes

All personnel who may enter and exit the experimental area include: experimental personnel, logistic personnel, equipment maintenance personnel, management personnel and outsiders (including item transporters and visitors). According to the authorization of different personnel at different times, they can enter different areas and the entrances of different areas Set up personnel or automatic monitoring measures to ensure laboratory safety.

There must be a relatively independent population to enter the third or fourth biosafety experimental area. Usually, measures such as registration access, authorized entry, and automatic monitoring are set up at this entrance to control the entry of personnel.

Personnel entering the experimental area remove all daily clothes in the clean clothes changing room, walk through the shower room, and wear special clean work clothes in the protective area in the protective clothing changing room. If they enter the Level 4 biosafety experimental area, they need to change the inner protective clothing . When leaving, take off the protective clothing in the protective clothing changing room, take a shower, and then enter the clean clothing changing room to put on daily clothes. This design is more conducive to protecting the environment outside the protected area.

If there is more than one core laboratory in the experimental area, it is necessary to set up a corridor. Personnel entering the protection area can enter the experimental auxiliary area through this corridor, such as preparation room, warehouse, etc., or enter different core laboratories. Corridors in the Level 4 Biosafety Experimental Zone are usually circular.

Enter the core room of the tertiary biosafety laboratory through the buffer, and change clothes in the buffer if necessary. If you enter the core room of the positive pressure suit type 4 biosafety laboratory, you must wear positive pressure protective clothing in the outer protective clothing change room and walk through the chemical shower room to enter. When leaving, take a chemical shower before entering the outer protective clothing change room and take off the protective clothing. This design can reduce the possibility of infection in protected areas such as corridors and preparation rooms, and can prevent cross-infection between core laboratories.

The staff entering the core laboratory must wear other personal protective equipment, such as gloves, goggles, masks, head and face protection cover, etc. in addition to protective clothing.

Fourth, goods flow route

The items needed by the biosafety laboratory are mainly experimental consumables, samples, reagents, protective clothing for experimenters, etc. The animal biosafety laboratory also has animal feed, bedding, cages, and animal experiment dissection tools (including sharp objects). The goods flow route can take the following different methods according to different requirements.

(1) Items in and out can be crossed in the corridor of the protection zone

is suitable for ABSL-3 type a or b1 laboratory, and ABSL-4 laboratory.

The clean items are sent into the corridors of the protection zone through the double-door autoclave and the transfer window, and then are brought into the core laboratories through the transfer window or with people. The contaminated articles in ABSL-3 laboratories are surface-sterilized in the core laboratories and then transferred to the corridor for packaging, and then passed through the biosafety double-door autoclave after sterilization. The contaminated items in the ASBL-4 laboratory must be sterilized by a biosafety sterilizer set in the laboratory before being transmitted.

Clean work clothes or inner protective clothing are sterilized and sent to the laundry room outside the protection area for cleaning, and then autoclaved to the protective clothing changing room.

Try not to use sharp instruments as much as possible. All sharp objects that can be handled should be placed directly in a sealed, puncture-resistant container that can be handled, and the container should be affixed with corresponding warning labels in obvious places.

Large equipment, such as animal cage racks, biological safety cabinets, etc., enter the experimental protection area through the equipment entrance and exit. The entrance and exit of the laboratory equipment of BSL-3 and ABSL-3 type a or b1 can be single-door, and type b2 of ABSL-3 The entrance and exit of the laboratory and BSL-4 and ABSL-4 laboratory equipment must be air-locked. When it needs to be shipped out, it must be disinfected in the laboratory first, and then sent out through the equipment entrance. When large equipment enters and exits, the core laboratories to enter or exit are all rooms where the experiment has been completed and has been disinfected.

(二) One-way flow of incoming and outgoing items without crossing

is suitable for ABSL-3 type b2 laboratory with multiple core rooms.

The clean items are sent into the corridors of the protection zone through the double-door autoclave and the transfer window, and then are brought into the core laboratories through the transfer window or with people. The contaminated items are sent to the dissection room through the contaminated corridor, and then passed out after being sterilized by the double-door autoclave in the dissection room.

The items in this program flow in one direction in the protection zone, and the clean section and the contaminated section are completely separated to avoid cross-contamination between the cores.

5. Laboratory animal entry, breeding, dissection and corpse treatment

The animal flow route of the animal biosafety laboratory starts from the entry of animals into the laboratory and ends with the disposal of animal carcasses. Small animal biosafety laboratories bred in isolators can share the corridors of the protected area as access channels, but small animals that have been dissected after the experiment must be autoclaved before they can be taken out. In the ABSL-3 type b2 laboratory, the animals move in one direction from the start point to the end point, without cross reciprocation. If the same experimental area has both large animal breeding rooms and small animal breeding rooms, it should be designed according to the one-way flow of animals.

The animal entrance is a place where animals enter the experimental area. After removing the outer packaging in the animal entrance room, the SPF small animals are sent into the experimental area through the transfer window; the ordinary large animals are washed and dried here.

The buffer room is a room that separates the experimental control area from the external environment. In the b2 laboratory of ABSL-3 and the ABSL-4 laboratory, there are usually two airtight doors at the entrance and exit of this room. The animal enters the buffer room through an airtight door from this entrance. After the animal enters, it is closed, and the control area personnel open another airtight door to bring the animal into the corridor of the protection area.

There are multiple core animal laboratories that require a corridor in the protection zone. The corridor in the protection zone is the traffic road for animals to enter the animal laboratories. Through this corridor, animals can enter different laboratories. Large animal control fences (doors) are set up in the corridors of the large animal laboratory to limit the position and direction of the large animals.

The animal breeding room is a contaminated area. Infected small animals and medium animals (such as dogs and monkeys) must be kept in negative pressure isolation ventilated cages or isolators; large animals (cattle, horses) are kept open, and the animal breeding area The staff work area is separated by a fence of sufficient height and strength. When performing animal experiment operations such as vaccination and blood collection or close observation, animal restraints are used to restrict animal activities, and different protective equipment is used for personal protection according to different levels of animal experiments.

If there are multiple animal laboratories in the b2 category of ABSL-3, a shared pollution corridor must be set up between the dissection room and the animal breeding room. The doors from each animal room to the polluted corridor and from the polluted corridor to the dissection room should be airtight doors. There is a large animal control bar (door) in the corridor to limit the position and direction of the large animal. An electric hoist can be installed at the top of the corridor to facilitate the transportation of large dead animals. The pressure in the contaminated corridor is lower than the animal room and higher than the dissection room.

Live animals should be euthanized in the autopsy room. If there are large animals, there must be an animal restriction bar in the autopsy room to meet the needs of injection, sampling, and sacrifice. The dissection of small or medium animals must be carried out on a biological safety cabinet or a negative pressure dissection table, and the dissection of large animals can be carried out using a common lifting dissection table. An electric gourd should be installed on the top of the dissection room to transport animal carcasses. Freezers or freezer rooms should be set up in the autopsy room to temporarily store animal carcasses.

Animal carcasses can be processed in different ways, such as biosafety double-door autoclaves, tissue processors, etc., according to the size and processing capacity of the carcass, but they can only be taken out after verification and proof of effective sterilization.

A positive pressure buffer or a pressure barrier is set at the entrance of the laboratory. The clean air is pressed to the inner and outer sides to ensure that the internal and external airflows do not cross each other.

In order to ensure the directional flow of laboratory airflow and easier control, the adjacent areas of the laboratory are set with a pressure difference of 10-25Pa according to different requirements. Usually the pressure gradient of the third-level large animal biosafety laboratory and the fourth-level biosafety laboratory is -25Pa.